The third cooking process is known as the Maillard response. This is a complicated science where many mixtures are framed at high temperatures by the response of diminishing sugars and amino acids. Since milk has a high substance of proteins and amino acids, the Maillard response will likewise add to the shade of biscuits which have been brushed with milk prior to baking giving a more obscure rich earthy colored tone.

These cooking processes all require high temperatures and happen when the biscuit surface is dry. The shading happens in the last phase of the baking system.

Rundown

We have seen that there are numerous complex physical and synthetic changes from the batter part of the biscuit during baking. These progressions are principally temperature and time subordinate and happen at various stages during baking. They might cover and associate. To know more information automatic biscuit making machine

Baking cycle time and temp

It is a valuable rearrangements to say that the design and surface of the biscuit is shaped in the primary portion of the stove, that the dampness expulsion is in the center and the shading happens at the last stage.

The stove configuration ought to hence give a fast hotness move toward the beginning of the prepare and keep an adaptable, clammy external skin of the batter piece to permit extension and lift. In the stove, the dampness ought to be eliminated productively from the mixture pieces and afterward extricated from the baking chamber. In the last zone(s) the outer layer of the biscuit will be dry and it will tone. Great parallel hotness move control is needed to keep an even shading and dampness content of the prepared biscuits.

The particular of the baking framework ought to be founded basically on the product(s) to be made and their necessities as far as design, surface, thickness, chomp, flavor and shading, exceptionally dull even shading or stood out foundation from features.

The attributes of the biscuits will decide the kind of hotness move (radiation, conduction and convection) which is proper at each phase of the baking system. This will characterize the broiler particular, the proper hotness evaluations and the zone lengths. The outline underneath shows the hotness appraisals (heat energy input per m2 of stove band) for quite a long time reason biscuit burrow broilers.

Hotness rating diagram for wafer, hard sweet and revolving formed biscuits

TechTalks Discussion

First time doing wafers I have a few issues

I'm attempting to make exceptionally thin saltines something like Italian Sfoglie, with various fixings to season. The batter is made with flour, potatoes pieces, and potato starch, with water and oil. I use ammonium bicarbonate as a substance raise.

At the point when we set up the batter it is delightful and delicate. The mixture we make has yeast and we pass on it to age for 16 to 18 hours.

After aging, we add the amonium bicarbonate and the mixture gets exceptionally muggy and we should add more flour to dry it, if the batter isn't extremely dry it is extremely difficult to cover as thin as we want, however it is exceptionally difficult to frame a ball since it should be dry to the point that it self-destructs in pieces that once we put on the laminator we should have the option to shape a batter and star overlaying and collapsing for multiple times, then, at that point, we diminish the thickness to 0 we should relax until it arrives at the right thickness, yet it is exceptionally disappointing and tedious in light of the fact that it breaks exceptionally simple and we need to start from the very beginning once more. We attempt to give the batter time to rest and we keep it warm and in a moist holder trusting it will be more malleable.

Is the manipulating time and rph vital? what might the best time? furthermore, at what rph could you propose please? My hardware is little, more like pastry kitchen style than industry, I have a kneader, a laminator, and a rotative broiler.

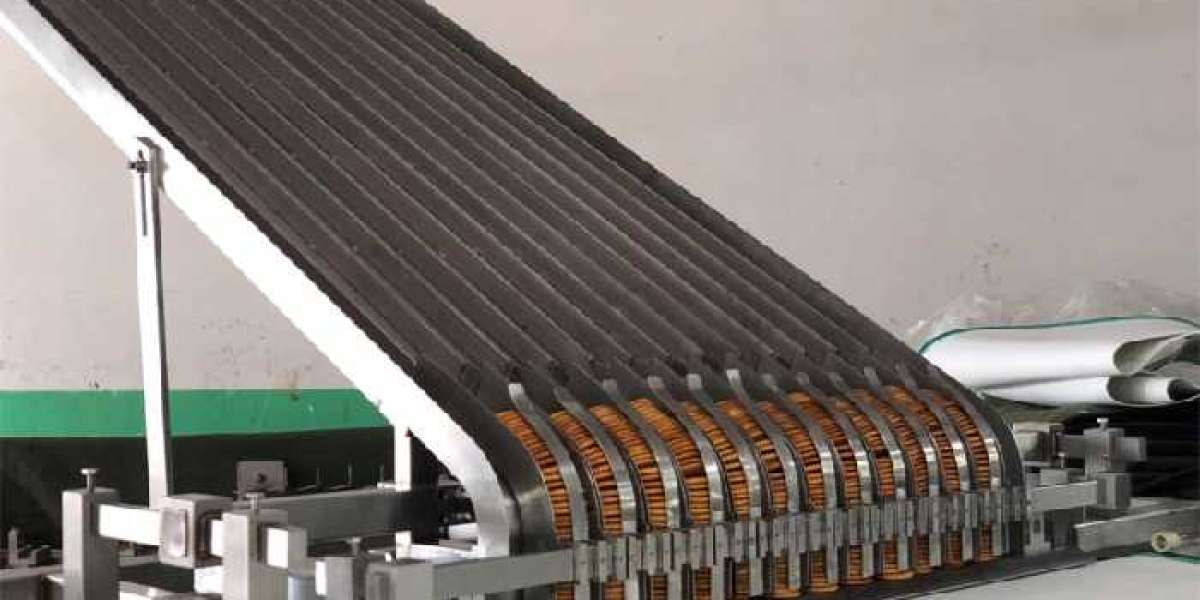

Changing the kind of belt in burrow stoves

As a previous item supervisor and presently an expert for burrow stove belts, I would be intrigued to request your involvement with changing the chief sort of belt utilized in your passage broiler and why. Did you change from strong steel belt to work belt or (different twisting) CB5-belt to Z-belt (moved baking stove belt)? Or on the other hand was it the other way around? Or on the other hand are there expectation and musings to accomplish something like this?

Little knocks and air rises on a delicate biscuit

Ee heated interestingly biscuits. We start with a delicate biscuit (two sorts with/without cocoa powder). We have a direct-terminated broiler, 40m long, with four-zone. We confronted with two issues: – the line of unbaked batter in the biscuit.