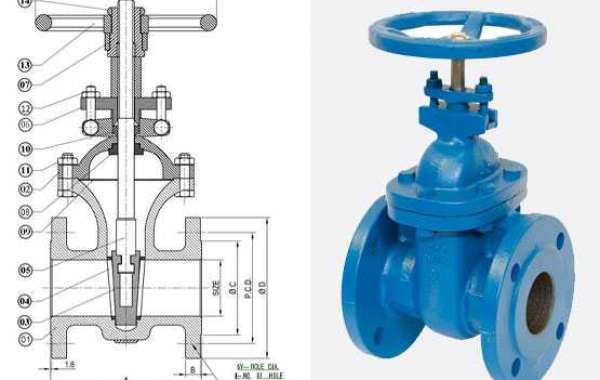

The most distinct section of the gate valve may be the sealing of passages from the gate or wedge, and seats.It could also be used for other types of applications, and ideal for both above ground and underground installation of stainless steel ball valve. In plumbing or piping field, it's used to start or stop the flow of liquid, however, not for controlling the flow, as the flow path in gate valves gets bigger when you start opening the valve.

A gate or wedge of gate valves moves perpendicular on the flow of the service. Anyhow, should you ever have to choose best gate valves to your industrial project, the best thing is to choose a reliable and reputable gate valve manufacturers. The two-piece wedge disc is seated between matching tapered seats by the body processes. This type is preferred the location where the body seats could possibly be distorted as a result of pipeline strain.

The split wedge includes two-piece construction which seats involving the tapered seats within the valve body. The two items of split wedge seat flat from the valve seats because the stem is moved downward, and so they move away from the valve seats once the stem is pulled upward.

Ball valves are durable, performing well after many cycles, and reliable, closing securely even after long periods of disuse. These qualities make them an excellent option for shutoff applications, where they are generally preferred to gates and globe valves. That said, they are doing lack fine control in throttling applications.

Although ball valves usually cost a little more than gate valves of comparable quality, the minimal saving just isn't worth the potential problems that are likely to follow. Moreover, ball valves seal much tighter – and so are therefore a smaller amount prone to leaks – than gate valves because of the 100 percent shut off characteristics.