All types of valve are essential to the operations of numerous versions of machinery and equipment, across many industries and applications. It’s hard to imagine a setting without a valve. That being said, not all valves is the same, and they are generally definitely not a 1 size fits all part.Choosing the best valve matters, so comprehending the applications, benefits, and advantages of each valve is the vital thing.A hollow wedge is often a variation of solid wedge apart from a hole in the center. The hollow wedge travels over the stem when the threaded stem is rotated, thus opening or closing the valve port.

The flexible wedge is also one-piece construction just like a solid wedge at stvvalves, but areas behind the seating surfaces are useless to provide flexibility. This construction compensates for adjustments to seat alignment for improved seating and keep the strength of a great wedge in the middle. This design offers better leak tightness and improved performance in situations with possibility of thermal binding.

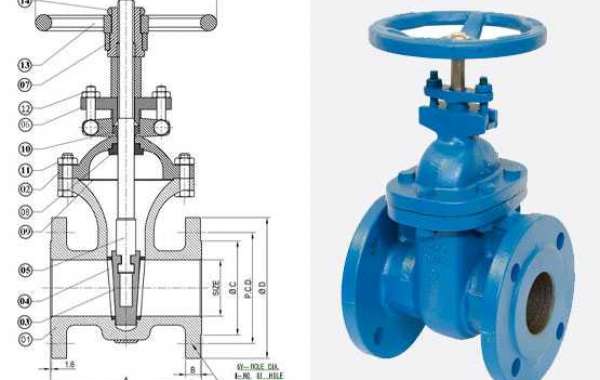

In the rising-stem sort of valve, the upper the main stem is threaded plus a nut is fastened solidly for the hand wheel and located in the yoke by thrust collars. As the hand wheel is turned, the stem moves up or down. In the non-rising stem valve, the lower end from the stem is threaded and screws in to the disc, vertical motion of the stem being restrained with a thrust collar. The rising-stem valve requires a greater quantity of space when opened.

These valves will also be very durable, and go on for a long time even under heavy use or very long periods without being used. They’re reliable, nonetheless they do not offer fine control, so it’s far better to stick with a ball valve in situations that you want a straightforward shut-off or start up without needing to tweak control. That’s why many people may know these valves as simply ‘shut off valves.’

Ball valves are also ideal in situations where an operator must turn things on / off, without losing pressure. They seal very well, since the ball blocks flow, and they are generally easy to function, only requiring an easy turn with the valve handle, that may then be visually confirmed.That being said, ball valves can cost a bit more than gate valves. Another potential disadvantage could be the space a ball valve requires to function.