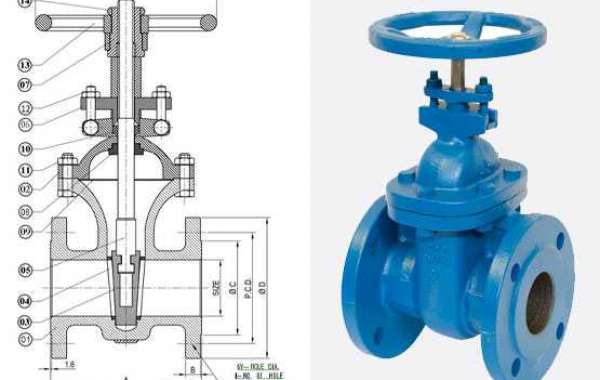

Gate valves at stvvalves.com and ball valves are two distinct individuals the valve family, and are generally useful for two different types of flow control.Gate valves possess a flat closure element that slides in and out with the media stream to open or close the valve. In the bronze-body gate valves which are frequently used in commercial and residential applications, a bronze disc moves up and down to spread out and close the valve. The valve is designed so the brass valve stem remains in the same height compared to the valve because the disc moves.

A Teflon packing kept in place with a threaded bonnet prevents leaks throughout the stem. Manual valves are actuated by turning a cast-iron handwheel.One from the main disadvantages from the gate valve is at its construction. Because it opens and closes having a screw handle attached to the gate, that handle failing could cause big problems — and the handles are unfortunately at risk of corrosion depending on the material used by construction, as well as the liquids or materials the valve has contact with. Choosing materials less susceptible to corrosion, like brass or stainless, will help.

Ball valves are actuated manually, through electric and pneumatic actuators as areas of flow control systems. One good thing about a manually actuated ball valve over a gate valve could be the handle position helps make the position of the ball an easy task to “see.”

Gate valves feature a sealing surface dividing the gate as well as the seats. As such, they are generally used each time a straight-line flow of fluid and minimum restriction is required. Because ball valves are a form of quarter-turn valve, they act differently. They use a hollow ball which can be both perforated and pivoted to regulate flow. The valve is open if the ball’s hole is line with all the flow. It closes when pivoted to 90 degrees from the valve handle, which lies flat, and level using the flow when open and perpendicular when closed. This makes it simple to visually confirm the valve’s status.

To settle the ball valve vs gate valve debate, we showed the discussion to leading Scottish industrial valve distributors, BM Engineering Supplies, who stock both valves types. They stated that this benefit of a ball valve vs a gate valve is because they seal much tighter, therefore driving them to better at avoiding leakage than gate valves.