Stone crushers are machines designed to crush large rocks and stones into smaller pieces for use in construction and other industries. There are several types of Stone Crusher available, each with its own unique features and capabilities. In this article, we will compare the different types of stone crushers and their performance.

Jaw Crusher

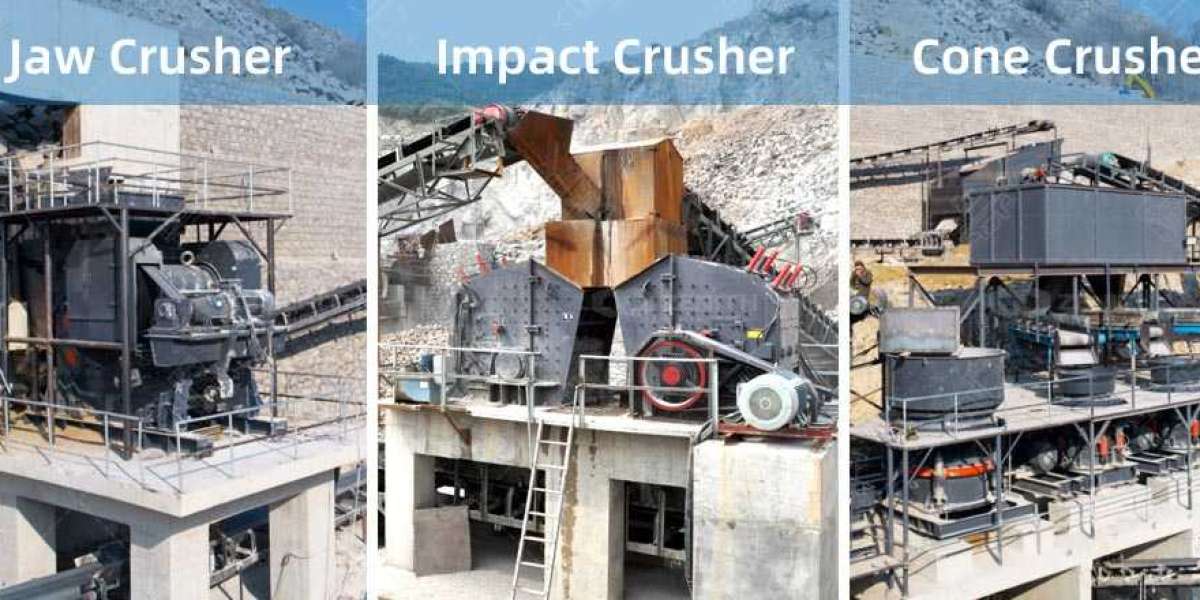

Jaw crushers are the most widely used type of stone crusher. They work by compressing the material between two plates, known as jaws. One of the plates is stationary, while the other plate moves back and forth. Jaw crushers are best suited for processing hard and abrasive materials, such as granite, ores, and minerals. They have high crushing efficiency and low operating costs.

Impact Crusher

Impact crushers are designed to crush materials through impact. They use a rotor to accelerate the material and then throw it against a stationary surface, such as a wall or anvil. This impact creates a high-speed collision that breaks the material into smaller pieces. Impact crushers are best suited for processing soft to medium-hard materials, such as limestone and gypsum. They have high crushing efficiency and a low cost per ton of material processed.

Cone Crusher

Cone crushers are designed to crush materials by squeezing them between a mantle and a concave. The mantle is a fixed component, while the concave rotates around the main shaft. Cone crushers are best suited for processing hard and abrasive materials, such as granite, ores, and minerals. They have high crushing efficiency and a low cost per ton of material processed.

Hammer Crusher

Hammer crushers are designed to crush materials by using a series of hammers. The hammers are mounted on a rotor that rotates at high speed, and the material is fed into the crusher through a feed hopper. Hammer crushers are best suited for processing soft to medium-hard materials, such as limestone and gypsum. They have high crushing efficiency and a low cost per ton of material processed.

In conclusion, different types of stone crushers have their own unique features and capabilities. The choice of crusher will depend on the type of material being processed, the required output size, and the cost per ton of material processed. Jaw crushers are best suited for processing hard and abrasive materials, while impact crushers are best suited for processing soft to medium-hard materials. Cone crushers and hammer crushers are best suited for processing hard and abrasive materials. Overall, stone crushers are essential machines in the construction and mining industries, and choosing the right type of crusher is crucial for achieving high crushing efficiency and low operating costs.