PCB Cleaners: Ensuring Pristine Circuit Boards

Printed Circuit Boards (PCBs) are the backbone of modern electronics, facilitating the flow of electrical signals and enabling the functionality of countless devices. However, during the manufacturing process, PCBs often accumulate contaminants, such as flux residue, solder balls, and dust, which can hinder their performance and reliability. To maintain the integrity of PCBs, specialized cleaning solutions and techniques are employed, making PCB cleaners an essential component of the electronics industry.

PCB cleaners are formulated to effectively remove unwanted substances from circuit boards without damaging their delicate components. They come in various forms, including solvents, cleaning agents, and cleaning machines, each designed to cater to specific cleaning requirements. The primary goal of PCB cleaners is to eliminate residues that may impact the electrical performance, insulation, and longevity of the circuitry.

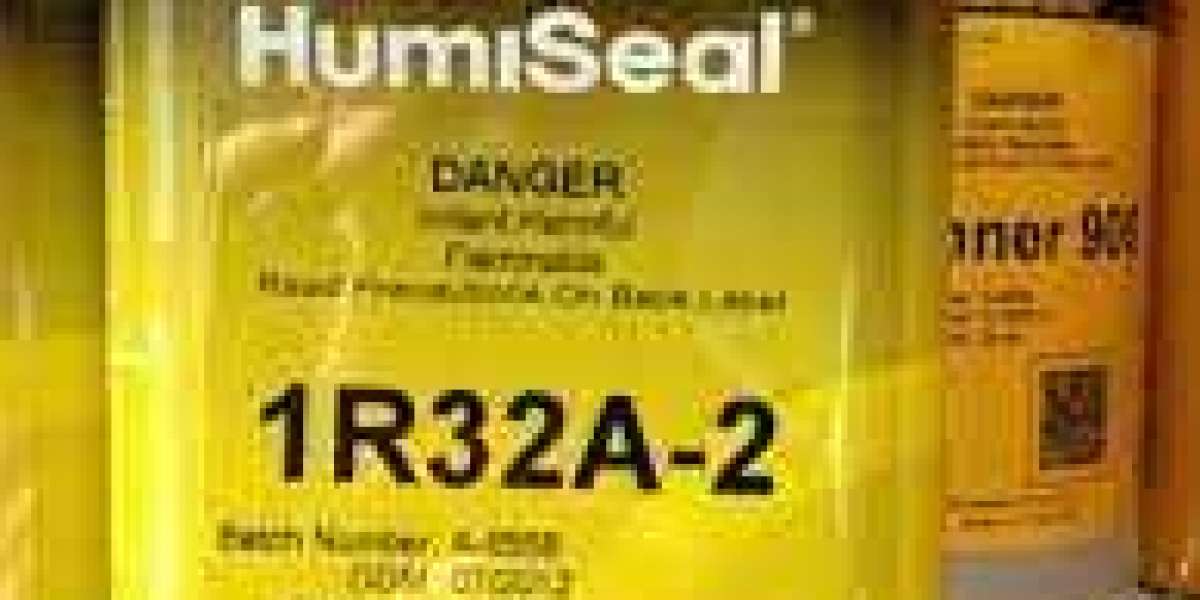

One popular type of PCB cleaner is the solvent-based cleaner. Solvents, such as isopropyl alcohol, acetone, and hydrocarbon-based solutions, are effective in dissolving and removing flux residue and other contaminants. They are particularly useful for cleaning surface-mount components, connectors, and the areas surrounding solder joints. Solvent-based cleaners are available in spray bottles, aerosol cans, and bulk containers, offering versatility and convenience for different cleaning applications.

Another widely used category of PCB cleaners is cleaning agents. These agents are typically water-based and incorporate specific chemicals to enhance the cleaning process. They can be formulated as concentrated solutions that are diluted with water before use. Cleaning agents are highly effective in removing stubborn contaminants, including solder paste, adhesives, and conformal coatings. They are generally safe to use on sensitive components, offering a balance between cleaning power and material compatibility.

In recent years, advancements in automation and robotics have revolutionized the PCB cleaning process. Robotic dispenser, also known as selective soldering machines, have emerged as an innovative solution for precise and controlled application of cleaning agents. These machines are equipped with programmable robotic arms, vision systems, and dispensing nozzles, allowing them to accurately apply cleaning agents to specific areas of the PCBs. Robotic dispensers ensure consistent and repeatable cleaning results, minimizing human error and optimizing the cleaning process.

The benefits of using robotic dispensers for PCB cleaning are numerous. They eliminate the need for manual handling of cleaning agents, reducing the risk of spills and exposure to hazardous chemicals. The programmable nature of robotic dispensers enables customized cleaning patterns and targeted cleaning, resulting in enhanced efficiency and reduced wastage of cleaning agents. Moreover, the integration of vision systems in these machines ensures precise application, even on complex PCB layouts with densely populated components.

Furthermore, robotic dispensers can be seamlessly integrated into existing production lines, improving the overall productivity and throughput of PCB manufacturing processes. They can be programmed to operate autonomously or be synchronized with other automated systems, such as pick-and-place machines, for a seamless and synchronized workflow.

In conclusion, PCB cleaners and robotic dispensers play crucial roles in maintaining the quality and reliability of printed circuit boards. With their ability to remove contaminants effectively without damaging delicate components, PCB cleaners ensure optimal electrical performance and longevity. The emergence of robotic dispensers has brought automation and precision to the cleaning process, offering improved efficiency, consistency, and safety. As technology continues to advance, the development of more sophisticated and specialized PCB cleaners and robotic dispensers is expected, further revolutionizing the electronics industry. - https://mectronics.in