Introduction

Stamping, a manufacturing process with roots dating back to ancient civilizations, has evolved into a modern marvel of precision engineering, innovation, and quality. In a world where efficiency and accuracy are paramount, stamping manufacturers play a pivotal role in creating a diverse array of products that touch our lives every day. From automotive parts to electronics, from household appliances to aerospace components, stamping manufacturers are the unsung heroes behind many of the items we rely on. This article explores the fascinating world of stamping manufacturers, shedding light on their techniques, technologies, and the significant impact they have on various industries.

The Art of Precision

At the heart of stamping manufacturing lies precision. The process involves pressing a die into a sheet of material, such as metal or plastic, to create intricate shapes and forms. The precision achieved in this process is nothing short of remarkable. Modern stamping manufacturers utilize advanced technology, including computer-controlled presses and sophisticated dies, to create parts with tight tolerances, ensuring consistent quality and performance.

The intricacy of the designs achievable through stamping is a testament to the artistry involved in the process. Skilled engineers and craftsmen work diligently to design dies that can produce complex shapes, patterns, and textures. Whether it's the elegant curves of a car's body panel or the intricate patterns on a decorative metal trim, stamping manufacturers bring these designs to life with meticulous attention to detail.

Driving Innovation

Innovation is a driving force in the world of stamping manufacturing. As industries evolve and customer demands change, stamping manufacturers must continually adapt to stay competitive. The development of new materials, such as high-strength alloys and lightweight composites, presents both challenges and opportunities for stamping manufacturers. They must innovate to optimize their processes for these materials, ensuring the resulting parts meet stringent requirements for strength, durability, and weight reduction.

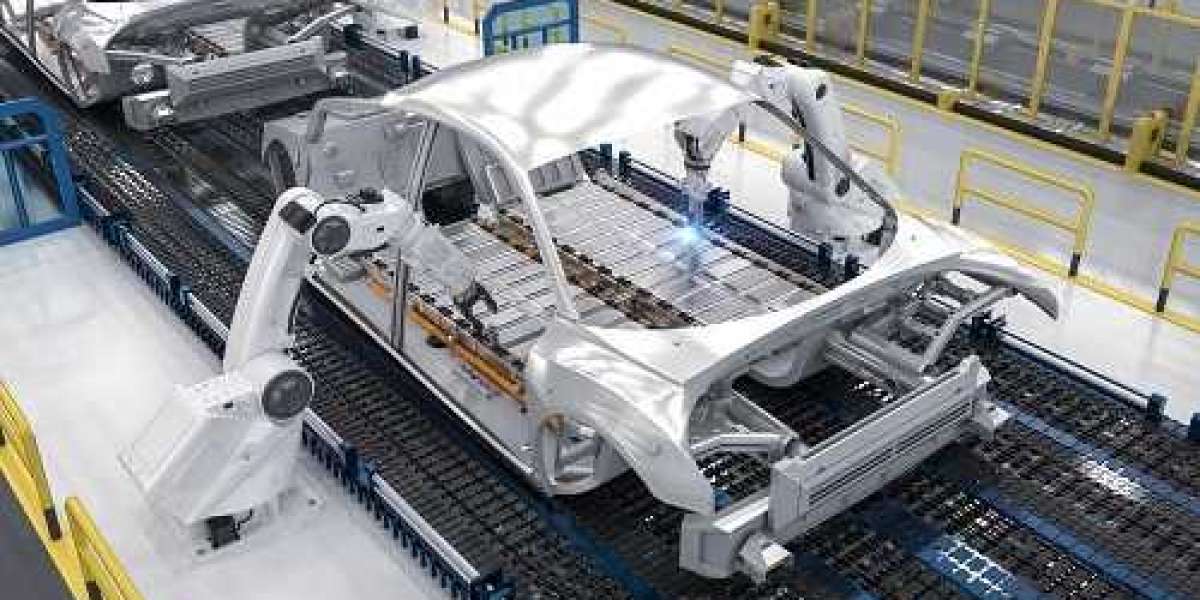

Additionally, advancements in automation and robotics have revolutionized the stamping industry. Automated presses, robotic material handling, and computer-aided design (CAD) software enable manufacturers to produce parts faster and with greater consistency. This increased efficiency not only reduces production costs but also allows for rapid prototyping and shorter lead times, which are critical in today's fast-paced manufacturing landscape.

Quality as a Cornerstone

Stamping manufacturers understand the critical importance of quality. Many industries rely on stamped components for their products, and any defects or inconsistencies can have far-reaching consequences. From safety concerns in the automotive sector to reliability issues in electronics, the quality of stamped parts must be uncompromising.

To ensure the highest quality, stamping manufacturers implement rigorous quality control processes. Advanced inspection techniques, such as laser scanning and digital imaging, are employed to detect even the tiniest deviations from the desired specifications. This commitment to quality not only meets industry standards but also earns the trust of customers who rely on these manufacturers for critical components.

Conclusion

Stamping manufacturers are the backbone of modern manufacturing, combining the art of precision with the drive for innovation and the commitment to quality. Their ability to create intricate parts with incredible accuracy is a testament to the evolution of a centuries-old process. As technology continues to advance and industries demand more from their suppliers, stamping manufacturers will remain at the forefront, shaping the future of various sectors and contributing to the products that enrich our lives.