Introduction

In the world of precision engineering and manufacturing, Swiss lathe manufacturers have carved out a distinct reputation for themselves. Renowned for their impeccable craftsmanship and cutting-edge technology, swiss lathe manufacturers have been instrumental in shaping industries that demand the highest levels of precision and quality. In this article, we will delve into the fascinating world of Swiss lathe manufacturing, exploring its history, innovation, and impact on various sectors.

A Legacy of Precision

The origins of Swiss lathe manufacturing can be traced back to the watchmaking industry of the 18th century. Swiss craftsmen revolutionized the way components were produced for timepieces, introducing techniques that enabled the creation of intricate and delicate parts. This legacy of precision laid the foundation for the modern Swiss lathe industry, which has expanded to encompass a wide range of applications beyond watchmaking.

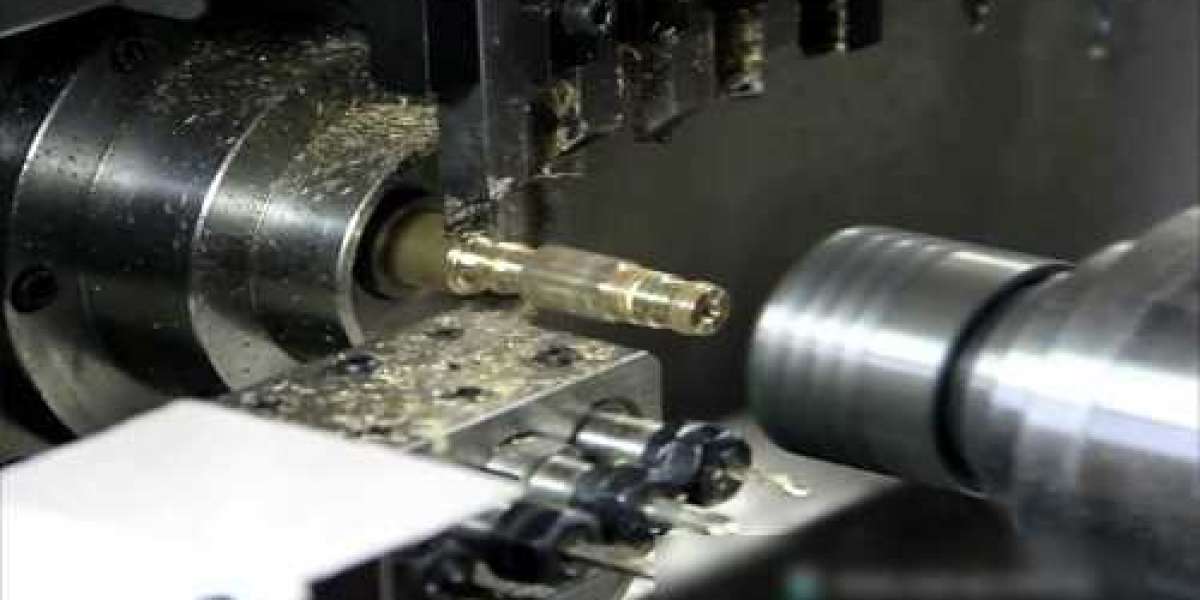

Key Characteristics of Swiss Lathes

Swiss lathes, also known as Swiss-type lathes or sliding headstock lathes, are designed to produce intricate components with high precision. Unlike traditional lathes, Swiss lathes have a sliding headstock that supports the workpiece close to the cutting tool. This design minimizes the deflection and vibration of the workpiece, enabling accurate machining even for small and delicate parts.

One of the key features that sets Swiss lathes apart is their ability to perform both turning and milling operations in a single setup. This multitasking capability reduces the need for transferring parts between machines, leading to improved accuracy and faster production times.

Innovation and Technology

Swiss lathe manufacturers are at the forefront of technological innovation in the manufacturing industry. Over the years, they have integrated advanced features such as computer numerical control (CNC), robotic automation, and high-speed machining into their machines. CNC technology allows for precise control over machining processes, ensuring consistent quality across batches of components. Robotic automation further enhances efficiency by automating tasks such as part loading, unloading, and tool changing.

High-speed machining capabilities of modern Swiss lathes allow for rapid material removal while maintaining tight tolerances. This is especially crucial for industries like aerospace and medical device manufacturing, where components require intricate detailing and precise measurements.

Applications Across Industries

Swiss lathe manufacturing has found applications across a diverse range of industries. From medical devices such as implants and surgical instruments to aerospace components like turbine blades and fuel nozzles, Swiss lathes play a pivotal role in producing high-quality, customized parts. The automotive industry benefits from Swiss lathe technology for manufacturing complex engine components, transmission parts, and precision gears.

The electronics sector also relies on Swiss lathes for creating connectors, pins, and other intricate components used in various devices. The versatility of Swiss lathes has contributed to their widespread adoption in industries that demand uncompromising precision.

Global Leaders in Swiss Lathe Manufacturing

Several Swiss lathe manufacturers have risen to prominence due to their commitment to innovation and quality. Companies like Tornos, Citizen Machinery, and Star Micronics have established themselves as global leaders in the field. Their machines are known for their accuracy, reliability, and ability to handle complex machining tasks.

Conclusion

The legacy of Swiss lathe manufacturing continues to shape the way precision components are produced across industries worldwide. With a rich history rooted in watchmaking, Swiss lathe manufacturers have evolved to embrace cutting-edge technology and deliver unparalleled precision. As demand for intricate and high-quality components grows, Swiss lathe manufacturers remain at the forefront of innovation, driving the evolution of precision engineering and manufacturing.