Introduction

In the world of advanced manufacturing, precision and efficiency are paramount. Among the remarkable innovations in this field is the Swiss Type CNC Lathe, a cutting-edge machining tool that has revolutionized the way intricate and high-precision components are produced. With its unique design and capabilities, the swiss type cnc lathe has become an indispensable tool for industries ranging from aerospace to medical devices. In this article, we delve into the intricacies of this remarkable machine and explore its significance in modern manufacturing.

The Essence of Swiss Type CNC Lathe

The Swiss Type CNC Lathe, also known as a Swiss-style lathe or Swiss screw machine, represents a pinnacle of precision engineering. Originating in Switzerland in the 19th century as a solution to produce intricate watch components, this machining marvel has evolved dramatically over the years, incorporating advanced automation and computer numerical control (CNC) technology. Today, it stands as a testament to precision manufacturing, capable of creating intricate parts with unparalleled accuracy.

Design and Operation

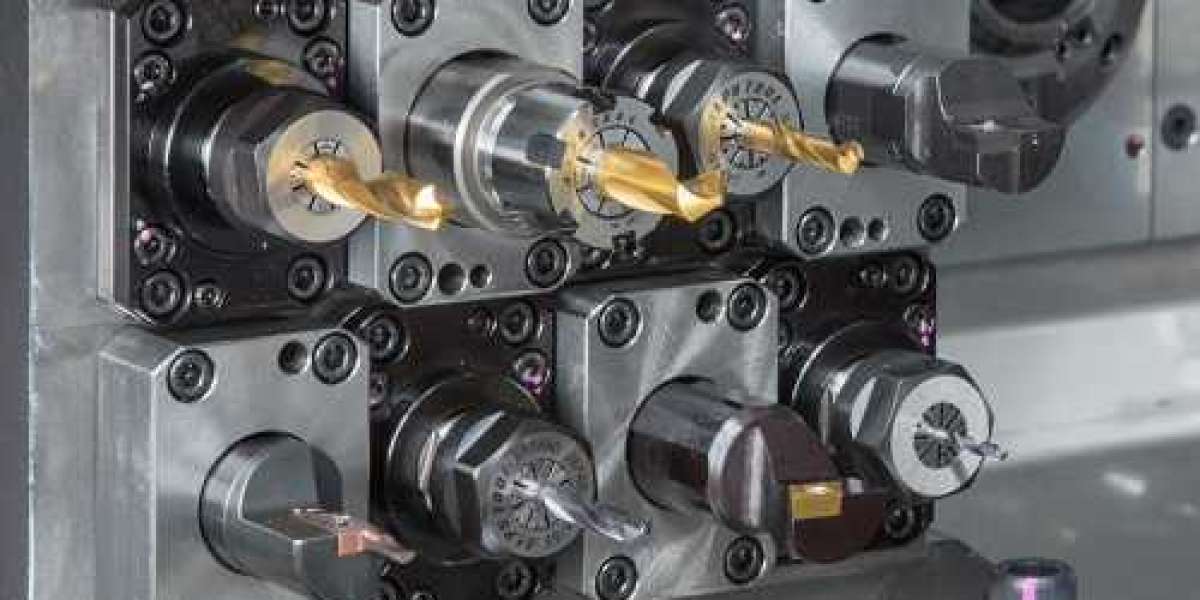

At the heart of the Swiss Type CNC Lathe's design is the sliding headstock, which sets it apart from conventional lathes. This headstock allows the workpiece to be guided through the tooling, enabling close-tolerance machining of small-diameter components. The fixed guide bushing supports the workpiece close to the cutting zone, minimizing vibrations and ensuring remarkable precision.

The machine operates with a synchronized combination of rotary tools, live tooling, and a sliding headstock. This synergy allows for simultaneous machining of multiple features in a single setup, reducing cycle times and enhancing efficiency. The combination of precise linear and rotary motion facilitates the creation of complex geometries, threads, and contours with exceptional accuracy.

Unparalleled Precision

The Swiss Type CNC Lathe's claim to fame lies in its extraordinary precision. With micro-inch-level tolerances achievable, the machine is tailor-made for the production of components that demand uncompromising accuracy. Industries like medical device manufacturing rely heavily on Swiss lathes to create implants, screws, and other critical components that must meet stringent quality standards.

Multi-Axis Machining

One of the most captivating features of the Swiss Type CNC Lathe is its ability to perform multi-axis machining. Modern iterations of this machine can have up to 12 axes, enabling intricate machining operations on various surfaces and angles. This capability is particularly beneficial when working with complex parts that require precise machining on multiple sides.

Material Versatility

Swiss lathes are not limited to specific materials; they excel at machining a wide range of materials, including metals like steel, aluminum, titanium, and even exotic alloys. This versatility makes them invaluable in industries that demand components with diverse material properties, such as the aerospace and automotive sectors.

Applications Across Industries

The Swiss Type CNC Lathe finds applications in a multitude of industries. From creating tiny components for electronics to producing complex aerospace parts, its versatility knows no bounds. Medical device manufacturers rely on Swiss lathes to craft implants and surgical instruments with impeccable accuracy, while the watchmaking industry continues to benefit from its heritage of precision.

Conclusion

The Swiss Type CNC Lathe stands as a testament to the marvels of modern engineering. Its unique design, multi-axis capabilities, and unparalleled precision have elevated it to a position of prominence in industries that demand the highest standards of accuracy and efficiency. As manufacturing continues to evolve, the Swiss Type CNC Lathe remains at the forefront, redefining what is possible in the realm of precision machining.