Crushing raw materials is a crucial step in many industrial processes. Whether you need crushed stone for construction, mineral extraction or recycled demolition materials, choosing the right crusher is essential. Here we compare three of the most common types of primary crushers used in various industries today.

Jaw Crusher

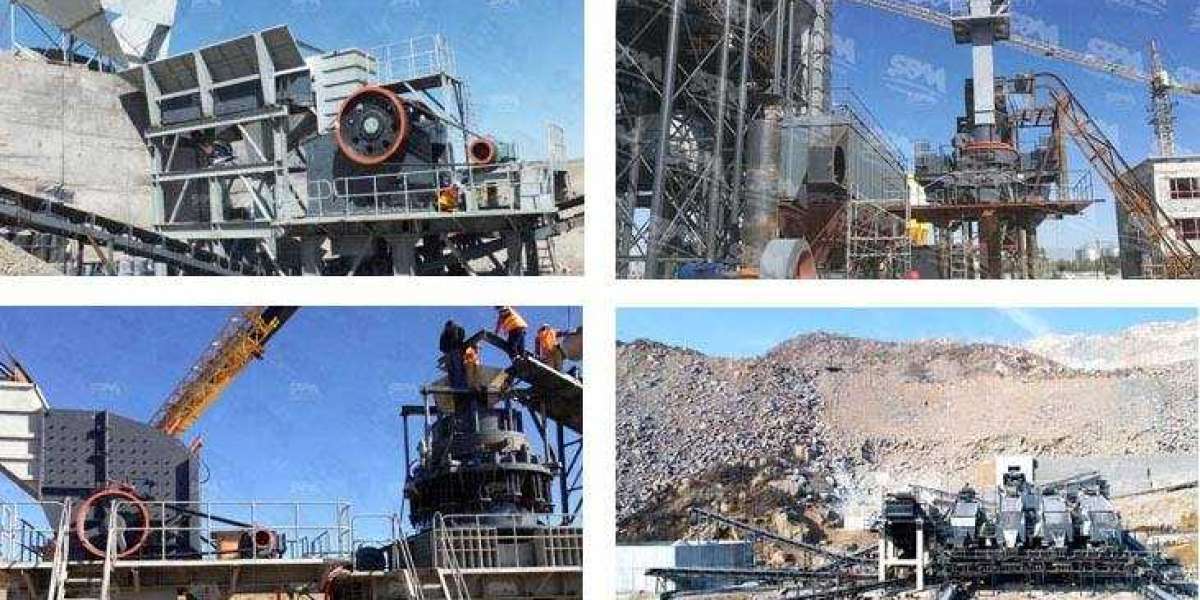

SBM's C6X Jaw Crusher is the workhorses of the crushing industry. Using compressive force, the jaw crusher has two massive steel jaws - one fixed and one moveable - that open and close like a mouth to crush rock or ore held between them. Jaw crushers are reliable, robust machines suitable for primary crushing of even the hardest materials. They are usually used for coarse crushing of harder materials. Materials exit from the bottom of the crusher after being crushed between the two jaws.

Cone Crusher

HST Cone Crusher utilize the same squeeze-and-shear principle as jaw crushers. The material is squeezed and sheared between the rotating cone mantle and the adjustable bowl lining. Cone crushers provide a finer crushed product than jaw crushers and are suited to secondary or tertiary crushing after a jaw crusher. They are widely used for medium-hard and hard rocks like basalt, granite and terracotta.

Impact Crusher

Rather than compression, impact crushers break rock by rapidly striking the material with a large, spinning rotor. The rock is thrown against heavy, hardened anvils or breaker bars lined with wear-resistant tiles. Impact crushers tend to produce more fines than jaw or cone crushers, making them ideal as primary or secondary crushers for recycling concrete and asphalt. They are suitable for processing soft and medium-hard rock.

Each crusher type has its advantages and disadvantages depending on factors like hardness of raw material, desired size/shape of crushed product, throughput capacity and cost. Choosing the right crusher is crucial for maximizing productivity in aggregate, mining and recycling operations.

difference between cone, jaw, and impact crusher: https://m.sbmchina.com/dynamic/differences-between-jaw-impact-and-cone-crusher.html